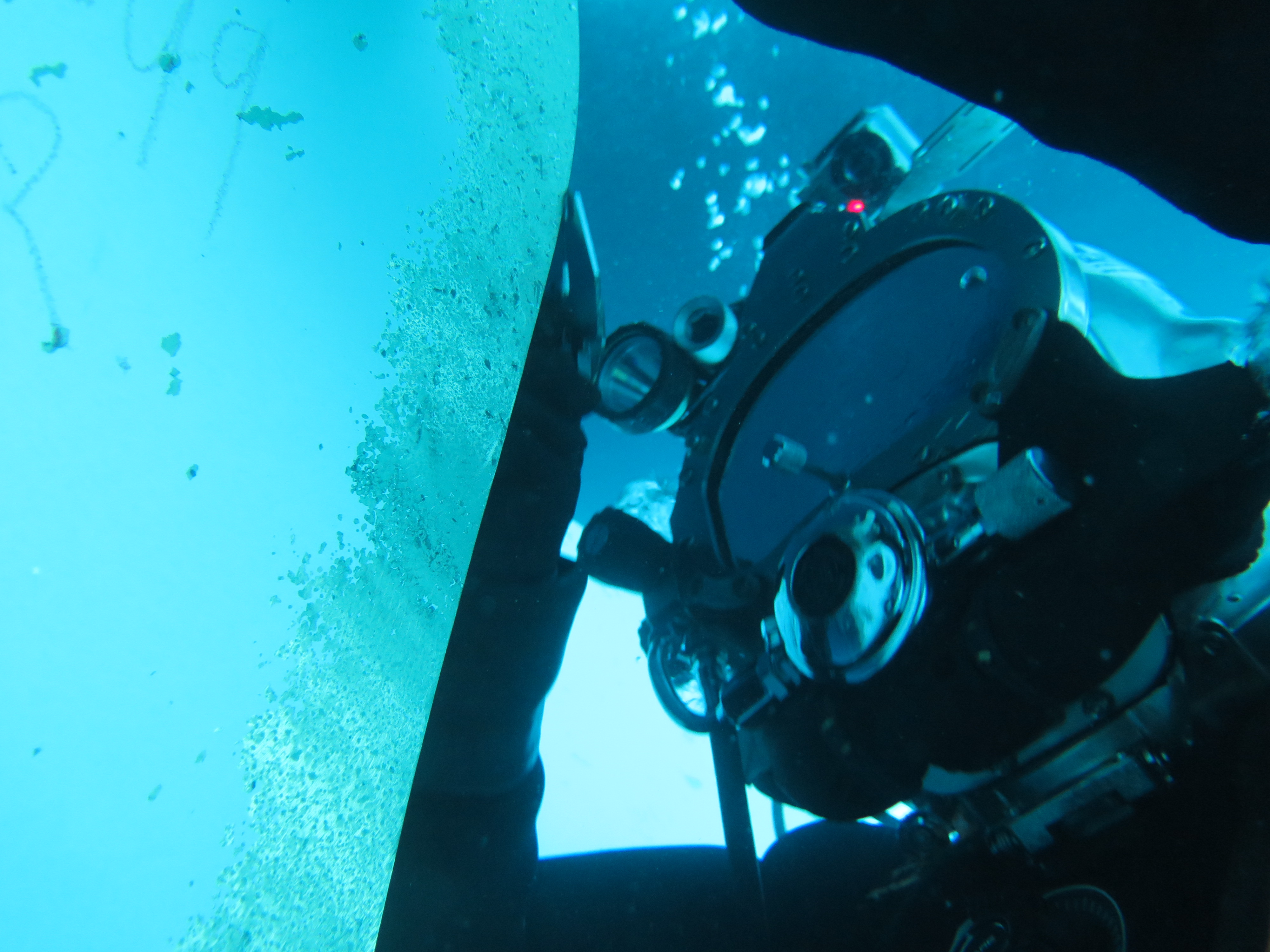

Propeller nozzle repair

Underwater repairs, maintenance and inspection for the international merchant fleet.

Propeller nozzle repair

To obtain the most thrust, a propeller must move as much water as possible in a given time. A nozzle will assist the propeller in doing this, especially when a high thrust is needed at a low ship speed.

As we already know, as the propeller blades rotate in the water, they generate high-pressure areas behind each blade and low pressure areas in front, and it is this pressure differential that provides the force to drive the vessel. However, losses occur at the tip of each blade as water escapes from the high pressure side of the blade to the low pressure side, resulting in little benefit in terms of pushing the vessel forward. The presence of a close fitting duct around the propeller reduces these loses by restricting water flow to the propeller tips.

The cross sectional area at the entrance of the nozzle is greater than at the trailing throat. Since the water density is constant, the water must accelerate from one to the other. Hence the water is already moving faster as it reaches the propeller than it would on a conventional open propeller. Therefore, more water is moved and more thrust created for the same input power and torque.

Under 24hrs & no drydocking

When damages occur on Propeller Nozzles FN Diving can exchange and repair them underwater in Situ. The total time for propeller nozzle repairare normally under 24 hrs, with no drydocking or down time. It’s a cost effective solution that is guaranteed to get you back on schedule fast. Feel free to contact us!